CEMENT

ESTANDA designs and manufactures anti-wear steel parts for the cement manufacturers and engineering companies, supplying them directly in more than 70 countries.

We cover the entire cement manufacturing process with castings for the equipment used in each and every one of its stages: Crushing, Grinding of raw and cement, Pre-Heaters, Furnaces and Cooling, Feeding systems,and other auxiliary systems.

ESTANDA also offers added technical solutions and services in product design and improvement, metallurgy and advice on the selection of the

best type of steel, Assembly Supervision and commissioning, After-sales Service and spare parts.

01

CRUSHING

Steel Hammers, Bars, Wear plates for the equipment used in the crushing stages of both the limestone and the clinker.

02

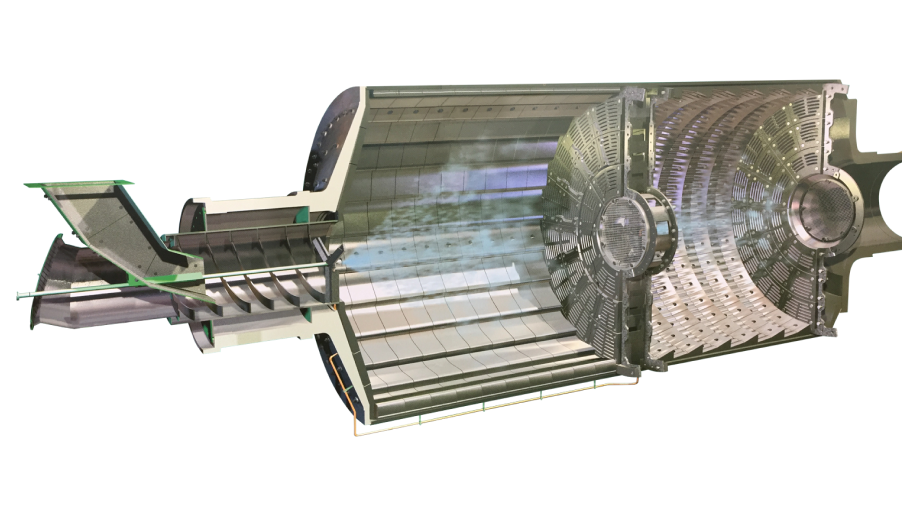

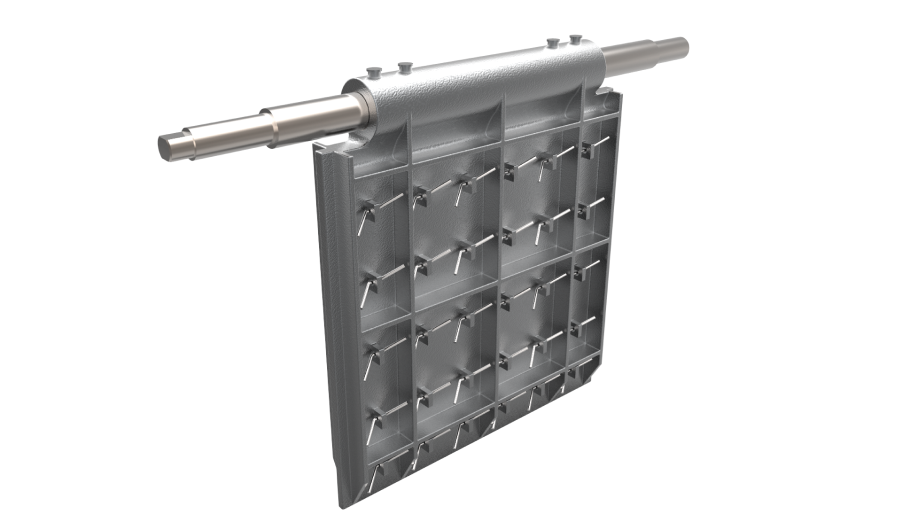

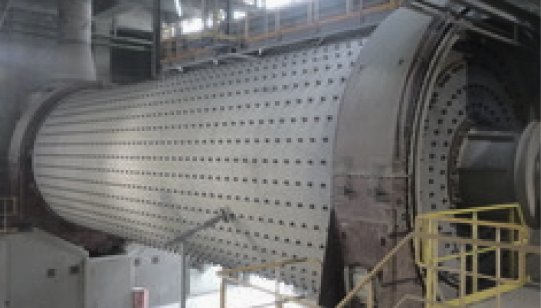

GRINDING OF RAW AND

GRINDING OF CEMENT

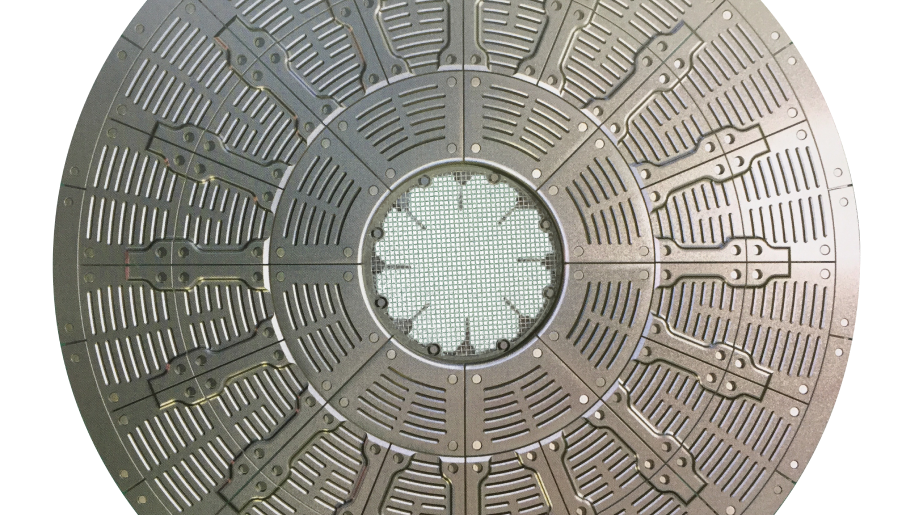

Anti-wear steel parts for the interior of mills for raw and cement: inlet headwall liners, shell liners, intermediate diaphragms, transfer diaphragms, central discharge diaphragms, and outlet diaphragms.

03

PRE-CALCINATION

Parts in refractory steel and resistant to chemical attack for the pre-calcination zone: immersion tubes, flap valves and diverter gates.

04

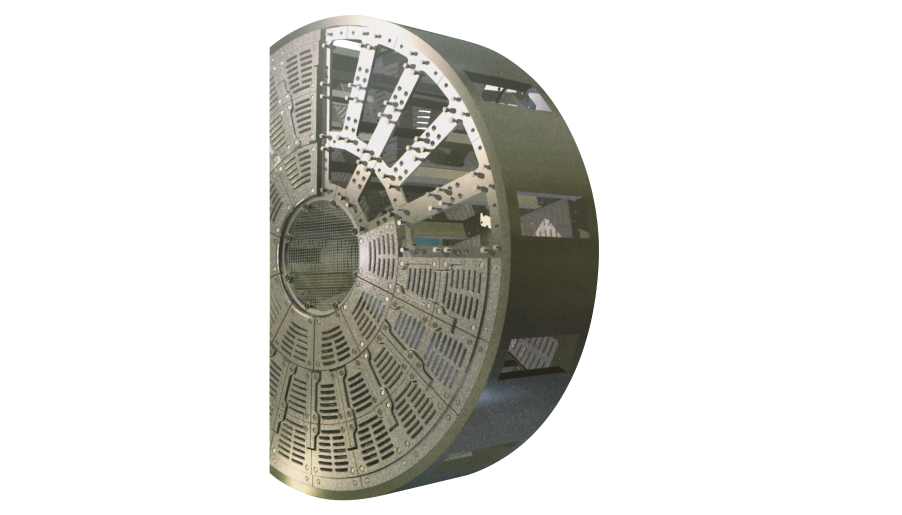

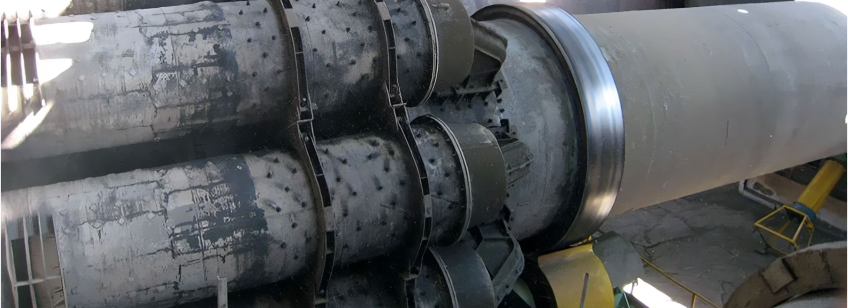

KILN

Parts in refractory steel for rotary raw cement calcination kilns: furnace inlet segments and furnace outlet segments.

05

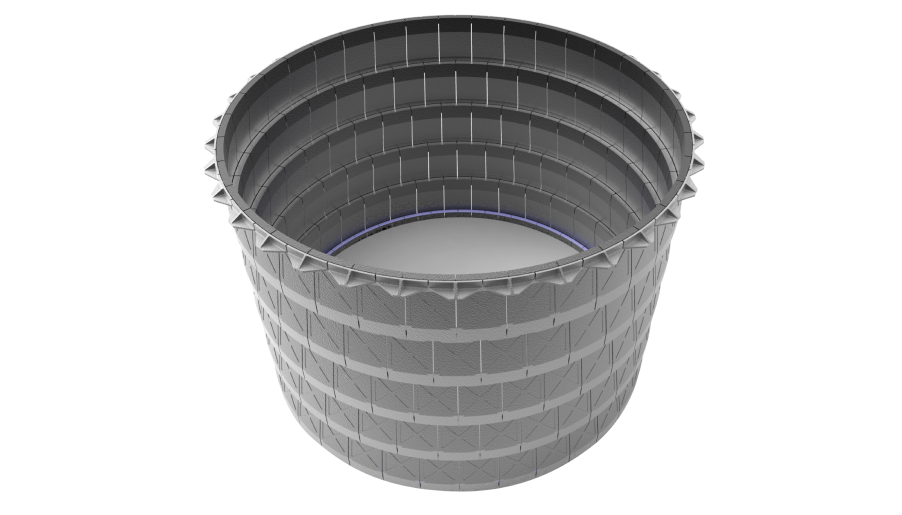

COOLER

Parts in refractory steel for the different types of clinker coolers: grate coolers and planetary coolers.

SOME CUSTOMER REFERENCES

Sector catalogues

Sector catalogues

ESTANDA Improvest® Self-Adjusting Diaphragms Catalogue ![]()

Grinding Optimisation Systems Catalogue. ![]()

Equipment and Components in Refractory Steels Catalogue. ![]()

Planetary Coolers Catalogue. ![]()